Mission Critical Data Centers

Environmental Sensor Calibration, Configuration and Quality Assurance/Checks (QAQC)

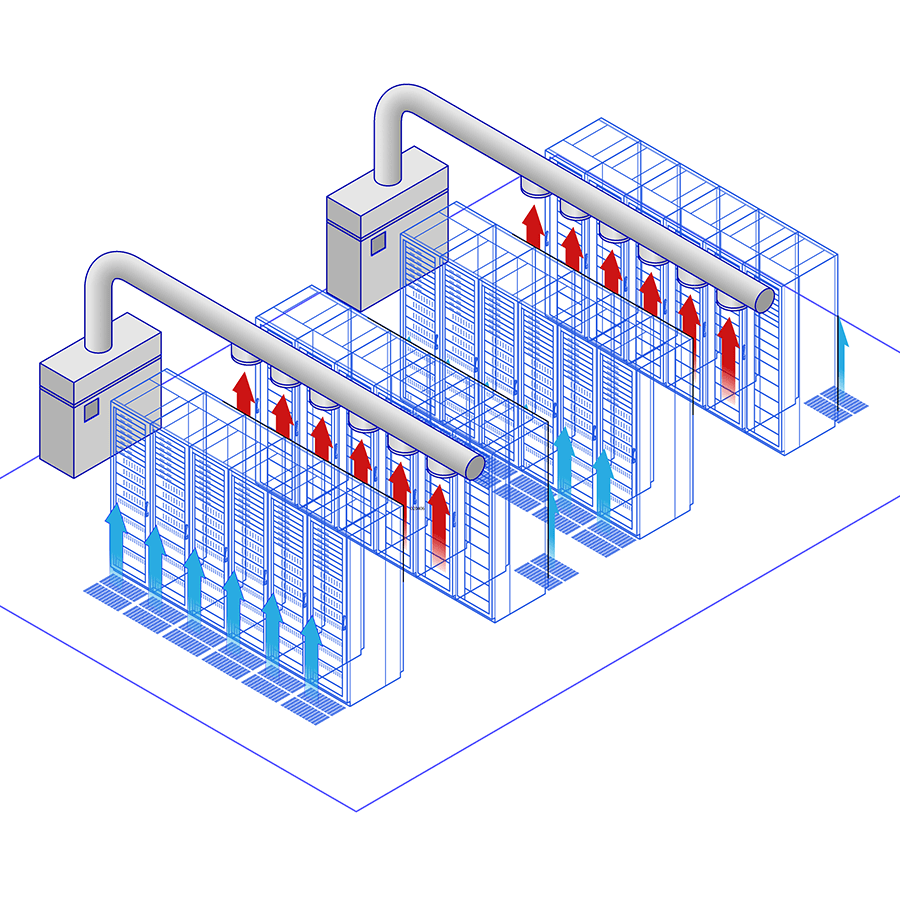

Data centers are required to be up and running 24 hours a day, seven days a week—environmental sensors and controls play a critical role in that requirement. SCI’s data center teams are equipped with expert knowledge and procedures to oversee the quality assurance and control of calibration, configuration, and post-commissioning health checks of critical environmental sensors. Temperature, differential pressure, water flow, and other environmental sensors are vital to providing accurate information. SCI knows accurate data is vital for the proper performance of your data center.

Every Measurement Matters: Critical Environmental Sensors

Data center monitoring is central to successful operation. When data centers are required to be up and running 24 hours a day, seven days a week,environmental sensors and controls play a critical role.

Regular calibration, configuration, and data center environmental monitoring—including a post-commissioning health check of critical environmental sensors such as temperature, differential pressure, water flow, and others—are vital to providing accurate data. We know that, on average, 24% of all critical environmental sensors are out of tolerance, which makes accurate data even more vital for the efficient performance of your data center.

Servicing Enterprise, Colocation or Hyper-scale Data Centers

Whether it is an Enterprise, Colocation, or Hyper-scale data center, inaccurate data from sensors and transmitters that have either failed or drifted out of tolerance can lead to significant over corrections over time, producing an overall system performance that is unknowingly below design specifications.

Even the most advanced Building Management System (BMS), Data Center Infrastructure Management (DCIM) or other facilities management systems software requires accurate sensor data to function properly and maintain your Power Usage Effectiveness (PUE) as designed.

As an ISO17025 accredited supplier with NIST traceable standards, all of us at SCI take pride in customers with confidence that their tools, equipment, and systems operate reliably and accurately.

General services for calibration, configuration, and repair of critical environmental instruments to be performed within the mission critical facility may include:

- Onsite calibration/configuration of end-to-end DCIM loops.

- System scaling adjustments (i.e. DCIM 4-20mA loop scaling)

- NIST traceable calibration of equipment and building sensors

SCI is Your Mission-Critical Auditing Partner

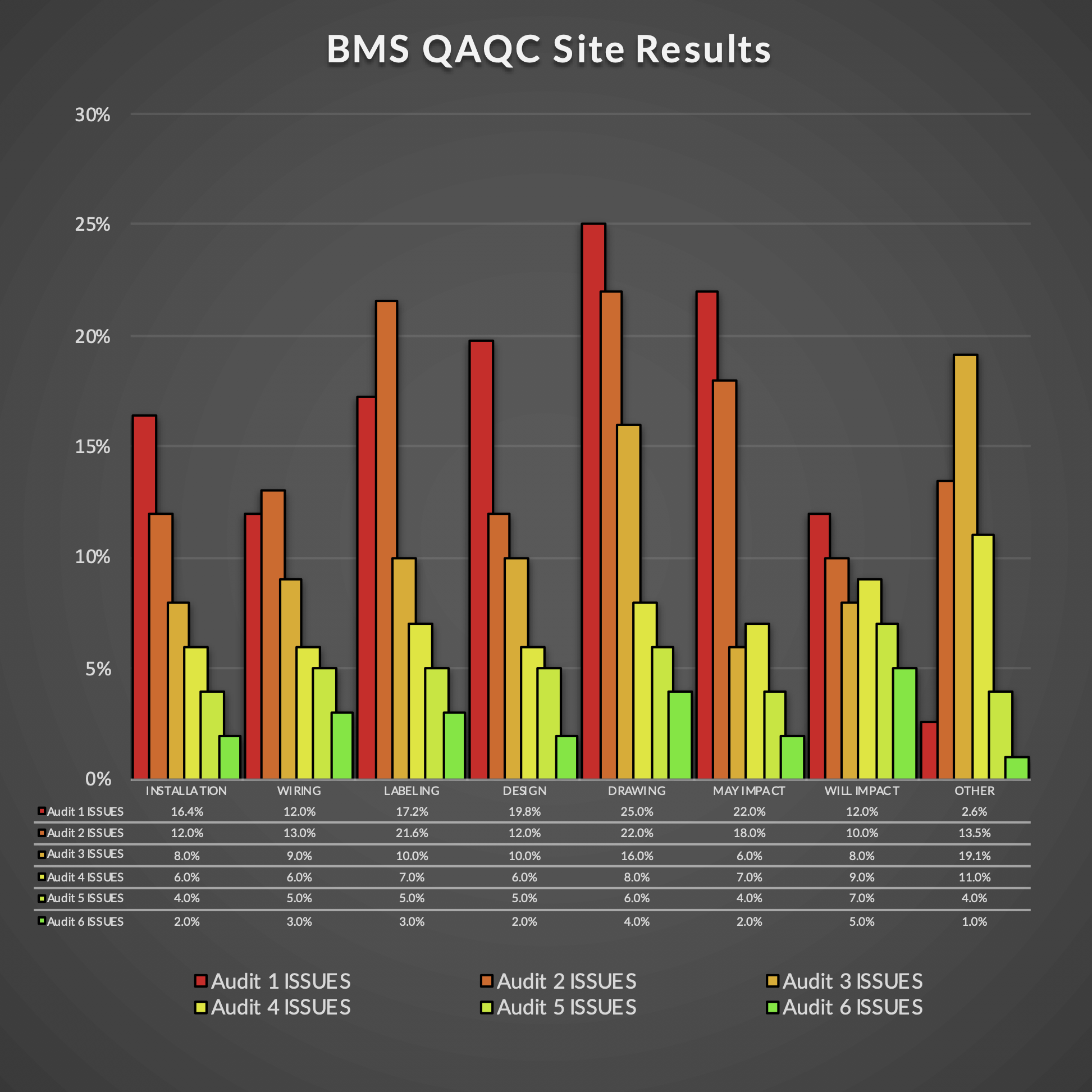

SCI has decades of experience in performing BMS inspection audits during the commissioning/pre-turnover phases of current and upcoming data center projects. Historically, customers find hundreds of issues after building turnover, delaying full utilization of datacenter systems and requiring a significant amount of rework. Repairs and quality oversight ultimately often then fall on the new owner and their staff.

To reduce this effort, SCI can act as the project auditing contractor within the construction and commissioning phases of each project. This provides new owners with a means to ensure that contractors are adhering to specifications for installation, calibration, and commissioning of critical systems. This both ensures that repeat issues do not continue to resurface, and that contractors have incorporated procedures to increase the quality of BMS equipment installations.

Specializing in BMS and DCIM Quality Assurance and Control

Where commissioning contractors provide general oversight, our auditing role dives deeper into critical building management system controls and instrumentation. We help to ensure devices are installed per specifications, drawings, and manufacturer installation guidelines. This work provides a higher level of confidence that devices are installed in a manner that will provide optimal measurement and control over the life of the installed equipment, and ultimately less cost.

QA/QC Overall Services include:

- Installation and wiring inspections

- Point-to-point checkout inspections

- Validation of BMS drawings to ensure as-builts reflect the actual final BMS installation

- Support and/or guidance to BMS and low-voltage subcontractors to mitigate quality issues and validate onsite calibration and point-to-point procedures

- Reports on findings and recommendations, including resolution of potential design issues

- Training for owners and contractors on common issues and best practices

Review of sensors and other instruments include, but not limited to:

- Dry bulb temperature

- Relative humidity

- Wet bulb/dew point temperature

- Liquid pressure

- Air and water flow rate/totalization

- Level

- Analytical

- Immersion temperature

- Air differential pressure

- High static switches

- Gas detection

- PLCs

- Switches

- Breakers

- Safety equipment

Just-in-Time Shipping

The Ship-in-Place (SiP) Program focuses on select critical environmental control devices that require repeat calibration, recertification, and usage configuration management. Fully calibrated and accepted inventory-controlled material will be maintained at both the customer's and SCI’s locations for immediate or just-in-time delivery of sensors, PLCs, switches, breakers, safety equipment, and other critical environmental instruments.

Services include:

- Application engineering

- Inspection

- Preservation

- Labeling

- Packaging

- Material

- Handling/shipping

- Software (firmware) and hardware upgrades

- Environmentally controlled inventory at SCI

All services coincide with the appropriate standards and industry knowledge for testing, shelf life, calibration, transportation, and storage under ANSI, OSHA, ASTM, or other industry standards.

Need a quote for products or services? Click here to submit a Request For Quote.Request A Quote